Â

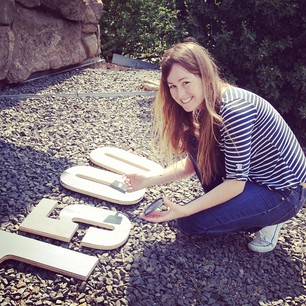

Last week our 1500 Riverside Ave. sign was in poor condition, flapping in the wind. Now we have these beautiful painted numbers, made on our CNC router by Lenny Scovel, our in-house-magical-shop-master-genius-extraordinaire. Of course, half of the credit goes to Meryl, who is very proud of the bold choice she made for the font. Â

Â

The CNC router, a computer controlled router, makes seemingly painstaking cuts much easier because the router literally does the work for you using a CAD (computer aided design) file of your design. CAD files are typically made with a CAD program such as TurboCAD (what the boys at Sears Trostel use), AutoCAD, EasyCAD, SqueezyCAD... If this is something you don't have access to, we offer a CAD drawing service here so don't let fear of this technology limit your design ideas. If you have any projects coming up in the future, instead think about how you could take advantage of this technology and drop by to see us here at Sears Trostel to get a quote... if you didn't know the address beforehand, you should all have it by now.

Below is another example of the work that the CNC router can do.

Â

Â

%20(1).JPG)

.JPG)

.JPG)

.JPG)