Winter Demonstration Saturdays

February 19, 2018

Saturdays are a great time to stop by Sears Trostel and learn something new.

Ask questions and try products for yourself as our knowledgeable staff spends an hour each Saturday demonstrating tools, finishes, and discussing woodworking techniques — while building fun projects in the process. There’s a different topic each week.

Demonstration Saturdays are 9:30 - 10:30 am at our Riverside store. There’s no need to register and it’s FREE of charge. Come in and join us!

During the Winter series of Demonstration Saturdays from February 24 to March 31, we’ll go through the steps to build a piece, using a variety of Festool tools, woods and other products.

Schedule:

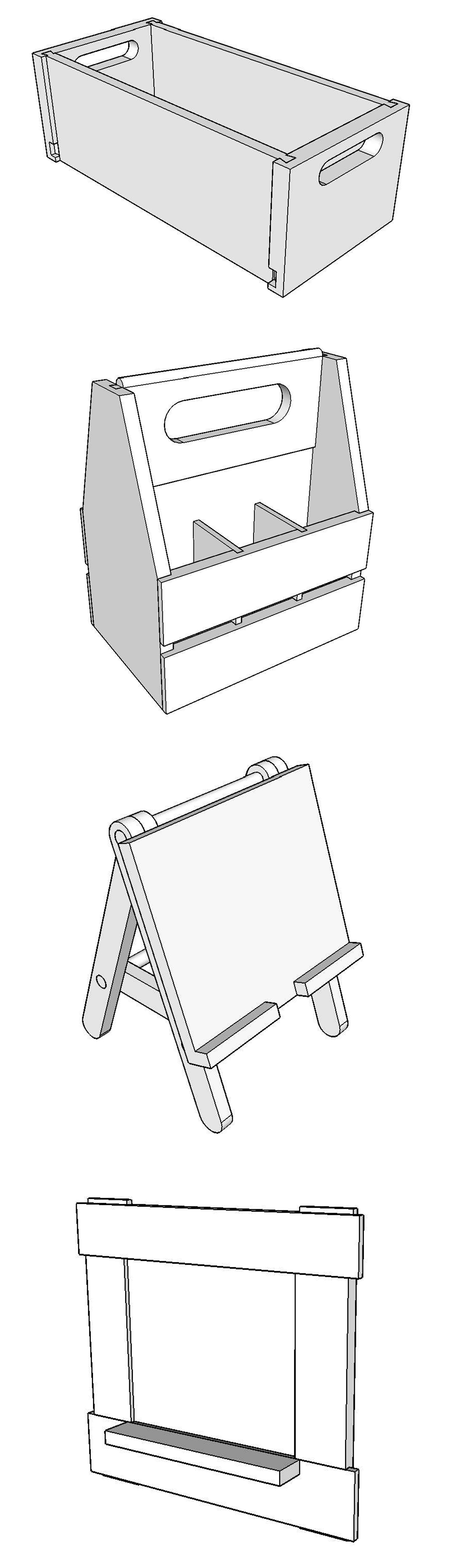

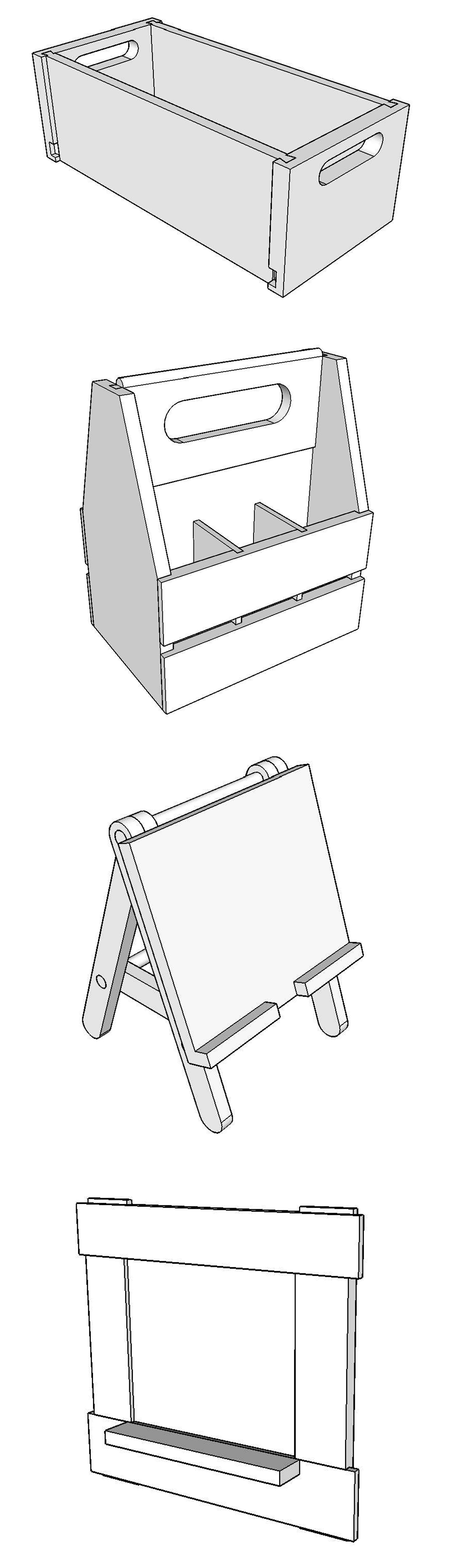

February 24 — Small Tool Crate/Carrier

March 3 — 6-Pack Carrier

March 10 — Cell Phone Charging Easel

March 17 — Message Board & Key Hanger

March 24 — Medicine Cabinet (wall-hanging) using the Kreg Jig system, including pocket screw joinery, hardware and concealed hinge jigs.

March 31 — Stains and Finishes. We’ll be applying General Finishes stains and finishes and discuss the differences between, and when to use, oil-based and water-based finishes/stains.

See you next Saturday!

Sears Trostel Lumber & Millwork

1500 Riverside Ave.

Fort Collins, CO 80524

Read More...

Ask questions and try products for yourself as our knowledgeable staff spends an hour each Saturday demonstrating tools, finishes, and discussing woodworking techniques — while building fun projects in the process. There’s a different topic each week.

Demonstration Saturdays are 9:30 - 10:30 am at our Riverside store. There’s no need to register and it’s FREE of charge. Come in and join us!

During the Winter series of Demonstration Saturdays from February 24 to March 31, we’ll go through the steps to build a piece, using a variety of Festool tools, woods and other products.

Schedule:

February 24 — Small Tool Crate/Carrier

March 3 — 6-Pack Carrier

March 10 — Cell Phone Charging Easel

March 17 — Message Board & Key Hanger

March 24 — Medicine Cabinet (wall-hanging) using the Kreg Jig system, including pocket screw joinery, hardware and concealed hinge jigs.

March 31 — Stains and Finishes. We’ll be applying General Finishes stains and finishes and discuss the differences between, and when to use, oil-based and water-based finishes/stains.

See you next Saturday!

Sears Trostel Lumber & Millwork

1500 Riverside Ave.

Fort Collins, CO 80524

Primed Mouldings In Fort Collins and Denver Area - Poplar Finger Joint Primed Benefits

February 14, 2018

Products created from a natural wood source can create a unique aura about them whether it be a simple butcher block atop a counter top or a complete moulding and trim installation. The creativity surrounding the use of a natural product, especially wood, within the home can change the appearance of a room in an absolute instance. Further, depending on the intended product application, wood can be much easier to clean and will withstand even more traffic, stains, or other potential damage over other commonly used materials for interiors. Over the long haul, a natural wood selection made for potentially any purpose will be the best choice over time.

One of the more commonly used species of lumber is poplar wood. The versatility of this particular wood and its ability to configure together seamlessly, increases its demand in uses in interior construction. Poplar comes from a relatively fast-growing tree and is often used for not only lumber, but also pulp purposes.

Poplar lumber products include the unique finger joint double primed products available in a range of sizes for a complete range of applications around your home or commercial project.

A finger joint is a woodworking mechanism used to interlock similar but separate pieces of wood into a cohesive length that is stronger than the original material. The two or more pieces are cut in opposite fashion so that, like interlocking “fingersâ€, the joint comes together and then is typically held together with some type of glue or adhesive for a strong and sturdy bond.

Often used in varying box constructions and long length boards, finger joints or comb joints can be used for anything from the construction of a small jewelry box to an entire set of interior mouldings. Also, finger joint allows for elongating pieces of wood for such items as baseboards, mouldings and S4S Lumber.

The finger joint creates an incredibly strong adhesion and thus can push the length of boards extensively without a risk of any structural insecurities. For this reason, finger joint poplar is a good choice for moldings which can come in lengths up to 16 feet long.

A beneficial option in poplar lumber, is the Sears Trostel Double Primed and Double Sanded finger joint lumber and mouldings. These poplar pieces come double-sanded and double-primed and are immediately ready for painting after installation or prior depending on the use and installation process. The double priming allows for a more smooth and clean look on the wood allowing for little to no extended sanding prior to a painting.

A beneficial option in poplar lumber, is the Sears Trostel Double Primed and Double Sanded finger joint lumber and mouldings. These poplar pieces come double-sanded and double-primed and are immediately ready for painting after installation or prior depending on the use and installation process. The double priming allows for a more smooth and clean look on the wood allowing for little to no extended sanding prior to a painting.

The double sanded and double priming can also impact the pocketbook of a homeowner in a positive way following the installation. When considering the different woods and products one should consider the added costs of the full installation, priming, and finishing of the product in their total budget. The double primed and double sanded poplar products add an advantage to the speedy completion of a project by knowing that only one coat of paint will be necessary to finish the product. Less money being spent for finishing and less time wasted are both benefits of a previously sanded and primed piece of wood.Â

Instead of using precious resources having to sand, prime, and then add multiple coats of paint to woods, the double primed option comes ready to absorb all of the color in a single coat of paint. Once applied, the finished product will be seamless with little to no evidence of graining and less manual jointing on long spans. An absence of knots in these finger jointed mouldings is also one of the main benefits.

Another advantage of finger jointed poplar involves the diversity for which there are multiple applications based on available sizes. Â The typical long lengths of finger joint poplar allow for less on-site manual transitions and added strength. Â Whether you choose to use raw poplar or double primed and double sanded finger joint poplar you will see the benefits of poplar and understand why poplar is one of the most popular options for a variety of different uses.

Eased edge moldings, including base, case, and headers are all available options to consider. These profiles offer a clean look to fit most styles in any room or house. The mouldings can also be installed and then painted quickly and efficiently with the final coat of paint. Â

Eased edge moldings, including base, case, and headers are all available options to consider. These profiles offer a clean look to fit most styles in any room or house. The mouldings can also be installed and then painted quickly and efficiently with the final coat of paint. Â

For decades, Sears Trostel has served our community with quality and integrity providing custom wooden countertops, wood floors, cabinets, John Boos Blocks, and other wooden assessments, when and where applicable. We are proud to offer the best value without compromising any of the quality or customer service you would expect from the business with a history of doing things the right way, the first time. Our manufacturing processes allow for unrivaled flexibility in custom profiles, and our commitment to quality has earned us the trust of our customers through Colorado, Wyoming, and the surrounding areas. Feel free to contact us today with your needs or visit our retail sales and showroom located at 1500 Riverside Avenue in Fort Collins, Colorado. For commercial and residential sales please call 970-482-1928 or for wholesale and manufacturing, 970-482-0222 or 800-950-1928 with any other general questions about our products and services. We can also be reached by email at Sales@sears-trostel.com as we look forward to showing you the effects quality beautiful natural woods can have.

Read More...

One of the more commonly used species of lumber is poplar wood. The versatility of this particular wood and its ability to configure together seamlessly, increases its demand in uses in interior construction. Poplar comes from a relatively fast-growing tree and is often used for not only lumber, but also pulp purposes.

Poplar lumber products include the unique finger joint double primed products available in a range of sizes for a complete range of applications around your home or commercial project.

Finger Joint Benefit

A finger joint is a woodworking mechanism used to interlock similar but separate pieces of wood into a cohesive length that is stronger than the original material. The two or more pieces are cut in opposite fashion so that, like interlocking “fingersâ€, the joint comes together and then is typically held together with some type of glue or adhesive for a strong and sturdy bond.Often used in varying box constructions and long length boards, finger joints or comb joints can be used for anything from the construction of a small jewelry box to an entire set of interior mouldings. Also, finger joint allows for elongating pieces of wood for such items as baseboards, mouldings and S4S Lumber.

The finger joint creates an incredibly strong adhesion and thus can push the length of boards extensively without a risk of any structural insecurities. For this reason, finger joint poplar is a good choice for moldings which can come in lengths up to 16 feet long.

Sears Trostel Double Primed Double Sanded Poplar

A beneficial option in poplar lumber, is the Sears Trostel Double Primed and Double Sanded finger joint lumber and mouldings. These poplar pieces come double-sanded and double-primed and are immediately ready for painting after installation or prior depending on the use and installation process. The double priming allows for a more smooth and clean look on the wood allowing for little to no extended sanding prior to a painting.

A beneficial option in poplar lumber, is the Sears Trostel Double Primed and Double Sanded finger joint lumber and mouldings. These poplar pieces come double-sanded and double-primed and are immediately ready for painting after installation or prior depending on the use and installation process. The double priming allows for a more smooth and clean look on the wood allowing for little to no extended sanding prior to a painting.The double sanded and double priming can also impact the pocketbook of a homeowner in a positive way following the installation. When considering the different woods and products one should consider the added costs of the full installation, priming, and finishing of the product in their total budget. The double primed and double sanded poplar products add an advantage to the speedy completion of a project by knowing that only one coat of paint will be necessary to finish the product. Less money being spent for finishing and less time wasted are both benefits of a previously sanded and primed piece of wood.Â

Instead of using precious resources having to sand, prime, and then add multiple coats of paint to woods, the double primed option comes ready to absorb all of the color in a single coat of paint. Once applied, the finished product will be seamless with little to no evidence of graining and less manual jointing on long spans. An absence of knots in these finger jointed mouldings is also one of the main benefits.

Varying Sizes and Application

Another advantage of finger jointed poplar involves the diversity for which there are multiple applications based on available sizes. Â The typical long lengths of finger joint poplar allow for less on-site manual transitions and added strength. Â Whether you choose to use raw poplar or double primed and double sanded finger joint poplar you will see the benefits of poplar and understand why poplar is one of the most popular options for a variety of different uses. Eased edge moldings, including base, case, and headers are all available options to consider. These profiles offer a clean look to fit most styles in any room or house. The mouldings can also be installed and then painted quickly and efficiently with the final coat of paint. Â

Eased edge moldings, including base, case, and headers are all available options to consider. These profiles offer a clean look to fit most styles in any room or house. The mouldings can also be installed and then painted quickly and efficiently with the final coat of paint.  For decades, Sears Trostel has served our community with quality and integrity providing custom wooden countertops, wood floors, cabinets, John Boos Blocks, and other wooden assessments, when and where applicable. We are proud to offer the best value without compromising any of the quality or customer service you would expect from the business with a history of doing things the right way, the first time. Our manufacturing processes allow for unrivaled flexibility in custom profiles, and our commitment to quality has earned us the trust of our customers through Colorado, Wyoming, and the surrounding areas. Feel free to contact us today with your needs or visit our retail sales and showroom located at 1500 Riverside Avenue in Fort Collins, Colorado. For commercial and residential sales please call 970-482-1928 or for wholesale and manufacturing, 970-482-0222 or 800-950-1928 with any other general questions about our products and services. We can also be reached by email at Sales@sears-trostel.com as we look forward to showing you the effects quality beautiful natural woods can have.

Sears Trostel Lumber and Reclaimed Wood Decorative Impacts

January 22, 2018

The beauty of wood in an intended natural state is unmatched and used for a variety of decorative and construction applications throughout homes and businesses everywhere. Most recently, reclaimed wood has been extremely in demand due to the second nature and purpose for many applications, creating an even more beautiful piece or focal point in a room or home.

The reclaimed wood utilizes a reinvention of the product typically taken from a variety of outdated sources but refurbished and transformed into incredible pieces of art or structural focal points. These pieces can be anything from a small serving tray, useful chopping block, or entire dining room table to constructional beams and siding in a room. The process of reclamation not only extends the life of a wood product but adds a distinct sense of flare and rustic decor when applied and designed correctly.

Known by a variety of names, reclaimed wood is often referred to as antique, distressed, or recovered timber or lumber. While the benefits of reclaimed timber are many, the fact that only so many older structures and pieces exist from which to extract the wood for use makes sourcing the lumber a tedious task in some instances. For these reasons, some manufacturers will attempt to recreate the aged wood look and pass off new wood as an alternative to reclaimed wood when certain reclaimed woods are not available in the time frame necessary for a project.

Some of the most utilized sources of securing old wood for reclaiming purposes include each of the following. One of the more traditional uses for reclaimed wood comes as a source from old barns, sheds, and buildings found either on property or elsewhere. Individuals who purchase a home with older structures occupying a portion of the land may like to reuse these buildings to create incredible displays inside their new home adding an instinctive piece of history and tradition to their magnificently created rustic decor.

One of the more traditional uses for reclaimed wood comes as a source from old barns, sheds, and buildings found either on property or elsewhere. Individuals who purchase a home with older structures occupying a portion of the land may like to reuse these buildings to create incredible displays inside their new home adding an instinctive piece of history and tradition to their magnificently created rustic decor.

For example, repurposing a barn door for use as a bathroom door or kitchen pantry sliding cover can be especially appealing. These have become increasingly popular over time and utilizing an actual door for the same purpose now inside a home fits beautifully with the reclaimed wood incentive. However, the same uses do not have to be a part of the repurposing for the lumber. Barn walls or lofts can be torn down and the wood repurposed to create siding inside a home or even furniture.

The wood could also be used for creating a mantle that once was the main beam across a barn or hand rail for a staircase that once led to a loft inside the older structure. These benefits not only add interesting conversation pieces in and around the home but also serve to increase the homely feel and setting of a room. Learn more about Barnwood at Sears Trostel. Another useful source of antique lumber comes from the wooden snow fences that stretch for miles across landscapes throughout Colorado and Wyoming and other parts of the United States. These snow fences still serve a purpose and are extremely cost beneficial to landowners where applied, but can also be a significant source of reclaimed wood utilization.

Another useful source of antique lumber comes from the wooden snow fences that stretch for miles across landscapes throughout Colorado and Wyoming and other parts of the United States. These snow fences still serve a purpose and are extremely cost beneficial to landowners where applied, but can also be a significant source of reclaimed wood utilization.

Much like barn wood, snow fences reclaimed from one’s own property can come with a history and story associated with them, but even when applied to a new home or into an entirely different area the beautiful wood sends a message to all who come into contact with the new use.

Due to the construction type of snow fences, this repurposed lumber is most appropriately used into the new construction of either siding, accents, or even hardwood floors. The ever changing colors and patterns applied by the outdoor weather over time can create unique rustic designs and change the initial appearance of any home or office, inside or out. Learn more about Reclaimed Snow Fence at Sears Trostel.

Also unlike the previous uses, live edge slabs are more traditionally used as tables, bars, or cutting boards. The tables can range in size depending on the initial wood product extending from large board room type pieces to a smaller dining room table top. The bars can be entirely constructed with a top created from a live edge slab and underneath paneling from perhaps an old wooden snow fence and cutting boards come in an extended variety of shapes and sizes.

Also unlike the previous uses, live edge slabs are more traditionally used as tables, bars, or cutting boards. The tables can range in size depending on the initial wood product extending from large board room type pieces to a smaller dining room table top. The bars can be entirely constructed with a top created from a live edge slab and underneath paneling from perhaps an old wooden snow fence and cutting boards come in an extended variety of shapes and sizes.

All of these uses from reclaimed wood help to create a unique and exciting rustic decor wherever they are applied. This look began as a necessary application extending from having to use wood in its’ most natural state for the purposes of building homes, barns and sheds but has now transformed into an organic composition for those hoping to achieve the look of natural beauty provided by one of nature’s most incredible products. The rustic decor achieved from utilizing reclaimed wood not only tells a story but transforms a room and its’ occupants back to a simpler time with a more easy-going and peaceful way of life.

For decades, Sears Trostel has served our community with quality and integrity. We are proud to offer the best value without compromising quality or customer service. Our manufacturing processes allow for unrivaled flexibility in custom profiles, and our commitment to quality has earned us the trust of our customers through Colorado, Wyoming, and the surrounding areas. Feel free to contact us today with your needs or visit our retail sales and showroom located at 1500 Riverside Avenue in Fort Collins, Colorado. For commercial and residential sales please call 970-482-1928 or for wholesale and manufacturing, 970-482-0222 or 800-950-1928 with any other general questions about our products and services. We can also be reached by email at Sales@sears-trostel.com as we look forward to showing you the effects quality beautiful natural woods can have. See the Sears Trostel Live-Edge Wood Slab Gallery.

Read More...

The reclaimed wood utilizes a reinvention of the product typically taken from a variety of outdated sources but refurbished and transformed into incredible pieces of art or structural focal points. These pieces can be anything from a small serving tray, useful chopping block, or entire dining room table to constructional beams and siding in a room. The process of reclamation not only extends the life of a wood product but adds a distinct sense of flare and rustic decor when applied and designed correctly.

Known by a variety of names, reclaimed wood is often referred to as antique, distressed, or recovered timber or lumber. While the benefits of reclaimed timber are many, the fact that only so many older structures and pieces exist from which to extract the wood for use makes sourcing the lumber a tedious task in some instances. For these reasons, some manufacturers will attempt to recreate the aged wood look and pass off new wood as an alternative to reclaimed wood when certain reclaimed woods are not available in the time frame necessary for a project.

Some of the most utilized sources of securing old wood for reclaiming purposes include each of the following.

Barnwood

One of the more traditional uses for reclaimed wood comes as a source from old barns, sheds, and buildings found either on property or elsewhere. Individuals who purchase a home with older structures occupying a portion of the land may like to reuse these buildings to create incredible displays inside their new home adding an instinctive piece of history and tradition to their magnificently created rustic decor.

One of the more traditional uses for reclaimed wood comes as a source from old barns, sheds, and buildings found either on property or elsewhere. Individuals who purchase a home with older structures occupying a portion of the land may like to reuse these buildings to create incredible displays inside their new home adding an instinctive piece of history and tradition to their magnificently created rustic decor.For example, repurposing a barn door for use as a bathroom door or kitchen pantry sliding cover can be especially appealing. These have become increasingly popular over time and utilizing an actual door for the same purpose now inside a home fits beautifully with the reclaimed wood incentive. However, the same uses do not have to be a part of the repurposing for the lumber. Barn walls or lofts can be torn down and the wood repurposed to create siding inside a home or even furniture.

The wood could also be used for creating a mantle that once was the main beam across a barn or hand rail for a staircase that once led to a loft inside the older structure. These benefits not only add interesting conversation pieces in and around the home but also serve to increase the homely feel and setting of a room. Learn more about Barnwood at Sears Trostel.

Snow Fence

Another useful source of antique lumber comes from the wooden snow fences that stretch for miles across landscapes throughout Colorado and Wyoming and other parts of the United States. These snow fences still serve a purpose and are extremely cost beneficial to landowners where applied, but can also be a significant source of reclaimed wood utilization.

Another useful source of antique lumber comes from the wooden snow fences that stretch for miles across landscapes throughout Colorado and Wyoming and other parts of the United States. These snow fences still serve a purpose and are extremely cost beneficial to landowners where applied, but can also be a significant source of reclaimed wood utilization.Much like barn wood, snow fences reclaimed from one’s own property can come with a history and story associated with them, but even when applied to a new home or into an entirely different area the beautiful wood sends a message to all who come into contact with the new use.

Due to the construction type of snow fences, this repurposed lumber is most appropriately used into the new construction of either siding, accents, or even hardwood floors. The ever changing colors and patterns applied by the outdoor weather over time can create unique rustic designs and change the initial appearance of any home or office, inside or out. Learn more about Reclaimed Snow Fence at Sears Trostel.

Live Edge Slabs

These pieces are in direct contrast to the typical paneling style and plank board components of pieces reclaimed from barns or old snow fences. Live edge slabs come directly from large trunks or sizeable branches depending on their intended use and provide a unique look at the interior markings of the tree. Also unlike the previous uses, live edge slabs are more traditionally used as tables, bars, or cutting boards. The tables can range in size depending on the initial wood product extending from large board room type pieces to a smaller dining room table top. The bars can be entirely constructed with a top created from a live edge slab and underneath paneling from perhaps an old wooden snow fence and cutting boards come in an extended variety of shapes and sizes.

Also unlike the previous uses, live edge slabs are more traditionally used as tables, bars, or cutting boards. The tables can range in size depending on the initial wood product extending from large board room type pieces to a smaller dining room table top. The bars can be entirely constructed with a top created from a live edge slab and underneath paneling from perhaps an old wooden snow fence and cutting boards come in an extended variety of shapes and sizes.All of these uses from reclaimed wood help to create a unique and exciting rustic decor wherever they are applied. This look began as a necessary application extending from having to use wood in its’ most natural state for the purposes of building homes, barns and sheds but has now transformed into an organic composition for those hoping to achieve the look of natural beauty provided by one of nature’s most incredible products. The rustic decor achieved from utilizing reclaimed wood not only tells a story but transforms a room and its’ occupants back to a simpler time with a more easy-going and peaceful way of life.

For decades, Sears Trostel has served our community with quality and integrity. We are proud to offer the best value without compromising quality or customer service. Our manufacturing processes allow for unrivaled flexibility in custom profiles, and our commitment to quality has earned us the trust of our customers through Colorado, Wyoming, and the surrounding areas. Feel free to contact us today with your needs or visit our retail sales and showroom located at 1500 Riverside Avenue in Fort Collins, Colorado. For commercial and residential sales please call 970-482-1928 or for wholesale and manufacturing, 970-482-0222 or 800-950-1928 with any other general questions about our products and services. We can also be reached by email at Sales@sears-trostel.com as we look forward to showing you the effects quality beautiful natural woods can have. See the Sears Trostel Live-Edge Wood Slab Gallery.

Beetle Kill Blue Stain Pine Lumber in Fort Collins

January 3, 2018

The mountain pine beetle is a species of bark beetle native to western North America, inhabiting forests from Mexico through the western United States and into the central portions of the Canadian province, British Columbia. An integral insect in the forests’ ecosystem, mountain pine beetles feed on older trees assisting in the youthful development of a natural forest state, allowing the maturation of younger saplings while preventing older, dead or decaying trees from robbing them of needed nutrients.

A rise in the earth’s average temperature over the past few years coupled with extended dry conditions and plenty of lodgepole pine trees have caused an epidemic and feeding frenzy of sorts from the mountain pine beetle community. The beatles lay eggs underneath the bark of an infected tree while introducing a blue stain fungus onto its’ new home. The fungus provided by colonization inhibits the housed tree from transporting water and essential nutrients inside and around to all areas of the tree, ultimately resulting in an untimely death for the endangered host.

Typically within two weeks, an attacked tree will be rendered lifeless as the beatles continue their attack while living out their life cycle. Once an attack is rendered a signal is sent to surrounding pine beetles in the area drawing even more insects to a specific tree under attack. Mountain pine beetles live approximately one to two years, much of which is spent beneath the surface of an inhabited tree’s bark except when emerging for attacks on a newly found subject.

A meaningful and beautiful use of a casualty tree involves the now discolored wood being repurposed in some form or fashion. Most often an infected tree will produce a wood with a natural grey or blue hue filled with distinct characteristics and a beautiful finish provided by the combination of a previous infestation and release of the blue fungus.

While the integrity of the wood is uncompromised the discoloration provides a shockingly beautiful color which can then be used for a variety of purposes. One of the more popular choices has been to use beetle kill wood in home construction. By utilizing the wood in every aspect from the framing to flooring in addition to accents and ceilings those leading the way in a useful repurpose of the pleasing and creative blue stain pine. Repurpose, may in fact be an inaccurate use of the term as the wood is often used just for its’ intended purpose but provides a unique look as opposed to the normal beauty and characteristic of regular pine. The beetle kill wood remains just as versatile and strong, providing a sustainable and suitable replacement depending on the desired purpose and look for construction.

If harvested within a five year period following an infestation and demise of the once live tree, all wood retained can be used for any number of projects including: paneling, flooring, cabinets, doors, and furniture. These pieces will have the unique blue hue which can often appear grey, purple, and a variety of different shades created from the fungus passed to the tree from the mountain pine beetle.

These varying shades allow wood projects completed with blue stain pine to exists in a natural state without any stain or paint to modify the color of the wood. Individuals concerned about the care of their wood and that of the environment can reap the benefits from a number of factors by electing to construct with blue stain pine as opposed to natural pine modified with a stain. Especially when attempting to reach a natural shade or darker colored aspect from the piece, wall or floor being made.

Further, by harvesting the pines that have been infected the trees are removed from the forest thinning out a potential catastrophic danger for the natural environment. Removal eliminates the dead wood early from the forest keeping it from becoming fully rotten and falling to the ground. These older trees serve little purpose except in a negative aspect providing a ground layer of kindling for potential forest fires if not removed. By both taking the wood out and then using it as intended the bonus created from the magnificent colors also makes the best of a bad situation created from the insect infestation.

This availability can help enhance any door, furniture, or room when wanting to create a natural looking state or environment without the needed use of chemicals. Artisans and designers everywhere are trending with the use of blue stain pine all provided from the natural state of its’ environment and resulting from an insect attack. What has transpired into an inordinate amount of attacks, resulting in acres of dead trees has been transformed into as much of a good thing as possible through innovation and design.

For decades, Sears Trostel has served our community with quality and integrity. We are proud to offer the best value without compromising quality or customer service. Our manufacturing processes allow for unrivaled flexibility in custom profiles, and our commitment to quality has earned us the trust of our customers through Colorado, Wyoming, and the surrounding areas. Feel free to contact us today with your needs or visit our retail sales and showroom located at 1500 Riverside Avenue in Fort Collins, Colorado. For commercial and residential sales please call 970-482-1928 or for wholesale and manufacturing, 970-482-0222 or 800-950-1928 with any other general questions about our products and services. We can also be reached by email at Sales@sears-trostel.com as we look forward to showing you the effects quality beautiful natural woods can have.

Read More...

Typically within two weeks, an attacked tree will be rendered lifeless as the beatles continue their attack while living out their life cycle. Once an attack is rendered a signal is sent to surrounding pine beetles in the area drawing even more insects to a specific tree under attack. Mountain pine beetles live approximately one to two years, much of which is spent beneath the surface of an inhabited tree’s bark except when emerging for attacks on a newly found subject.

A meaningful and beautiful use of a casualty tree involves the now discolored wood being repurposed in some form or fashion. Most often an infected tree will produce a wood with a natural grey or blue hue filled with distinct characteristics and a beautiful finish provided by the combination of a previous infestation and release of the blue fungus.

While the integrity of the wood is uncompromised the discoloration provides a shockingly beautiful color which can then be used for a variety of purposes. One of the more popular choices has been to use beetle kill wood in home construction. By utilizing the wood in every aspect from the framing to flooring in addition to accents and ceilings those leading the way in a useful repurpose of the pleasing and creative blue stain pine. Repurpose, may in fact be an inaccurate use of the term as the wood is often used just for its’ intended purpose but provides a unique look as opposed to the normal beauty and characteristic of regular pine. The beetle kill wood remains just as versatile and strong, providing a sustainable and suitable replacement depending on the desired purpose and look for construction.

Benefits of Beetle Kill Blue Stain Pine

The infestation and epidemic created by warmer and dry conditions that led to the demise of countless acres of pines throughout the inhabited region does come with a few benefits. While the destruction of trees is never a good thing, an ability to find a silver lining in the midst of a bad situation has helped to save other landscapes and benefit those who elect to use beetle kill pine for their construction projects.If harvested within a five year period following an infestation and demise of the once live tree, all wood retained can be used for any number of projects including: paneling, flooring, cabinets, doors, and furniture. These pieces will have the unique blue hue which can often appear grey, purple, and a variety of different shades created from the fungus passed to the tree from the mountain pine beetle.

These varying shades allow wood projects completed with blue stain pine to exists in a natural state without any stain or paint to modify the color of the wood. Individuals concerned about the care of their wood and that of the environment can reap the benefits from a number of factors by electing to construct with blue stain pine as opposed to natural pine modified with a stain. Especially when attempting to reach a natural shade or darker colored aspect from the piece, wall or floor being made.

Further, by harvesting the pines that have been infected the trees are removed from the forest thinning out a potential catastrophic danger for the natural environment. Removal eliminates the dead wood early from the forest keeping it from becoming fully rotten and falling to the ground. These older trees serve little purpose except in a negative aspect providing a ground layer of kindling for potential forest fires if not removed. By both taking the wood out and then using it as intended the bonus created from the magnificent colors also makes the best of a bad situation created from the insect infestation.

This availability can help enhance any door, furniture, or room when wanting to create a natural looking state or environment without the needed use of chemicals. Artisans and designers everywhere are trending with the use of blue stain pine all provided from the natural state of its’ environment and resulting from an insect attack. What has transpired into an inordinate amount of attacks, resulting in acres of dead trees has been transformed into as much of a good thing as possible through innovation and design.

For decades, Sears Trostel has served our community with quality and integrity. We are proud to offer the best value without compromising quality or customer service. Our manufacturing processes allow for unrivaled flexibility in custom profiles, and our commitment to quality has earned us the trust of our customers through Colorado, Wyoming, and the surrounding areas. Feel free to contact us today with your needs or visit our retail sales and showroom located at 1500 Riverside Avenue in Fort Collins, Colorado. For commercial and residential sales please call 970-482-1928 or for wholesale and manufacturing, 970-482-0222 or 800-950-1928 with any other general questions about our products and services. We can also be reached by email at Sales@sears-trostel.com as we look forward to showing you the effects quality beautiful natural woods can have.

The Beauty Real Wood Has to Offer

Hardwood is an investment

December 29, 2017

Wood itself has a long and storied history, being used for and in construction dating back thousands of years or more. The uses extend beyond building structures however, as boats, weapons, and protective pieces or barriers like shields and fences also often used the natural component. Uses even extended into everyday needs and still does today by providing fuel as a heat source, furniture for the home, and is even a major component of paper. The beauty of wood extends beyond its’ natural state and can still be utilized in the modern era by adding character and value to almost any project.

Whether you are contemplating an addition onto your home or office, building a brand-new structure from the ground up, or updating an existing interior and/or exterior considering wood as the basis for the project can pay immediate dividends. Depending on the overall goal of a project, wood provides a means by which many different factors can each be accomplished simultaneously.Â

From the floor to the ceiling, wood can change the outlook of a room or even an entire building almost immediately. Changing existing fixtures and surfaces into wood offers a variety of positive features both pleasant to the eye and pocket book. The wide array of available choices in wood is often surprising as modifications both small and large can be utilized when choosing wood as the base component on a project. Various colors and designs are all attainable with the different types of wood naturally available and on the market today.

The following are a few examples of areas where natural wood can take your home or office to the next level both inside and out:

From outlining doors and windows to providing a protective barrier for the wall, wooden trim and mouldings serve a variety of purposes. Most individuals are familiar with baseboards but crown molding is less common. While it can be used to cover imperfections in the drywall, crown molding serves the primary purpose of improving a room’s appearance.

Hardwood flooring is also much easier to clean, providing a quality appearance to everyone who walks into your room. Depending on the wood used and color decided upon, dust, dirt, and debris is also often less noticeable when on a hardwood floor as opposed to a carpeted surface.

Box beams provide the desired look of solid wood beams but at an affordable price. Box beams are perfect for remodeling or adding to existing rooms because they are relatively easy to install and quickly adds character to a room.  Â

Millwork is also extremely flexible in its’ use and finished design. In many occurrences, the millwork will be sold unfinished so that a buyer can apply their own colors, finishes, or paints to match where the piece or pieces are to be added within the structure or project area. Creating custom millwork today also extends beyond the prototypical “railing†frequently seen above fireplaces and doors to include extra detail on garage doors, plank ceilings, wall paneling, cabinets, and other encasement around architectural details in homes and buildings.Â

A wooden butcher block provides one of the best options for both durability and cleanliness inside a kitchen. Hardwood butcher blocks provide a clean, safe and beautiful surface.Â

For decades, Sears Trostel has served our community with integrity and quality. We are proud to offer the best value without compromising quality or customer service. Our manufacturing processes allow for unrivaled flexibility in custom profiles, and our commitment to quality has earned us the trust of our customers through Colorado, Wyoming, and the surrounding areas. Feel free to contact us today with your needs or visit our retail sales and showroom located at 1500 Riverside Avenue in Fort Collins, Colorado. For commercial and residential sales please call 970-482-1928 or for wholesale and manufacturing, 970-482-0222 or 800-950-1928 with any other general questions about our products and services. We can also be reached by email at Sales@sears-trostel.com as we look forward to showing you the effects quality beautiful natural woods can have.

Read More...

Whether you are contemplating an addition onto your home or office, building a brand-new structure from the ground up, or updating an existing interior and/or exterior considering wood as the basis for the project can pay immediate dividends. Depending on the overall goal of a project, wood provides a means by which many different factors can each be accomplished simultaneously.Â

From the floor to the ceiling, wood can change the outlook of a room or even an entire building almost immediately. Changing existing fixtures and surfaces into wood offers a variety of positive features both pleasant to the eye and pocket book. The wide array of available choices in wood is often surprising as modifications both small and large can be utilized when choosing wood as the base component on a project. Various colors and designs are all attainable with the different types of wood naturally available and on the market today.

The following are a few examples of areas where natural wood can take your home or office to the next level both inside and out:

Mouldings

Used in a variety of areas, wood mouldings can provide immediate improvements to a particular space or entire home when used correctly. Wooden types of trim used in homes literally varies from the floor to ceiling and is one of the most beneficial aesthetic improvements available.From outlining doors and windows to providing a protective barrier for the wall, wooden trim and mouldings serve a variety of purposes. Most individuals are familiar with baseboards but crown molding is less common. While it can be used to cover imperfections in the drywall, crown molding serves the primary purpose of improving a room’s appearance.

Flooring

Choosing custom hardwood flooring provides a variety of benefits extending beyond an increased resale value of the property. In today’s market, having custom hardwood floors is often an immediate selling point, giving your home a one of a kind look and typically raising the purchase price past any cost of installation. But the benefits do not end there.ÂHardwood flooring is also much easier to clean, providing a quality appearance to everyone who walks into your room. Depending on the wood used and color decided upon, dust, dirt, and debris is also often less noticeable when on a hardwood floor as opposed to a carpeted surface.

Beams

Solid wooden beams offer many positives including providing solid support while being extremely versatile. Exposed beams are also a trending consideration in real estate and having natural wood creates both a conversation piece and solid engineering design in many homes.Box beams provide the desired look of solid wood beams but at an affordable price. Box beams are perfect for remodeling or adding to existing rooms because they are relatively easy to install and quickly adds character to a room.  Â

Custom Millwork

Used both on a building’s interior and exterior, custom millwork adds a decorative aspect to any project. The appearance of millwork is much like the use of crown molding, as it enhances the outward look of a building or improves the feel of an interior room. Often, the special attention to detail in the characteristics of millwork can significantly raise both the price at resale and selling potential itself by providing a unique look not readily available in most real estate markets.Millwork is also extremely flexible in its’ use and finished design. In many occurrences, the millwork will be sold unfinished so that a buyer can apply their own colors, finishes, or paints to match where the piece or pieces are to be added within the structure or project area. Creating custom millwork today also extends beyond the prototypical “railing†frequently seen above fireplaces and doors to include extra detail on garage doors, plank ceilings, wall paneling, cabinets, and other encasement around architectural details in homes and buildings.Â

Wainscot

Essentially millwork on a much larger and less detailed scale, wainscoting provides both an improved appearance to an interior wall or hallway while serving the purpose of a high-end appearance. Similar to paneling, as the two are often used in relation, wainscoting typically appears on the lower portion of a solid wall and serves solely as a decorative feature in today’s home or office.Butcher Blocks

These unique pieces can spice up a kitchen simply from their immediate addition on top of an existing counter, built-in countertop, or a separate kitchen island cart made from all-natural wood. Serving a two-fold purpose, natural wood butcher blocks provide a pleasing sight and conversation piece in addition to providing a functional apparatus in the kitchen for your cooking enjoyment.A wooden butcher block provides one of the best options for both durability and cleanliness inside a kitchen. Hardwood butcher blocks provide a clean, safe and beautiful surface.Â

For decades, Sears Trostel has served our community with integrity and quality. We are proud to offer the best value without compromising quality or customer service. Our manufacturing processes allow for unrivaled flexibility in custom profiles, and our commitment to quality has earned us the trust of our customers through Colorado, Wyoming, and the surrounding areas. Feel free to contact us today with your needs or visit our retail sales and showroom located at 1500 Riverside Avenue in Fort Collins, Colorado. For commercial and residential sales please call 970-482-1928 or for wholesale and manufacturing, 970-482-0222 or 800-950-1928 with any other general questions about our products and services. We can also be reached by email at Sales@sears-trostel.com as we look forward to showing you the effects quality beautiful natural woods can have.